Perkins Specialized Transportation Contracting is pleased to present a “quantum leap” in specialized highway transportation for moving long cargo. The first unit in a series of a new breed of patented hydraulic platform highway trailers we call the QUANTUM™. The QUANTUM™ hydraulic transporter is a Perkins-designed and patented, professionally manufactured highway legal transporter with a 106’ long loading platform that is 10’ wide and can easily accommodate cargo up to 136’ long. Perkins hopes you will take the time to compare this transporter to the conventional mechanical highway trailer combinations you have used for years.

It is our belief that your use of the QUANTUM™ trailer could profoundly change the way shippers think about the way they design their long and/or delicate fabrications and have them moved throughout North America. The QUANTUM™ hydraulic transporter is designed to handle extremely long and/or wide payloads up for cargo from 160,000 lbs to 240,000 lbs (subject to state/provincial axle loading requirements along the routing). There is no assembly or disassembly required, which is a huge time savings compared to the Goldhofer, which must be assembled prior to mobilization or on site.

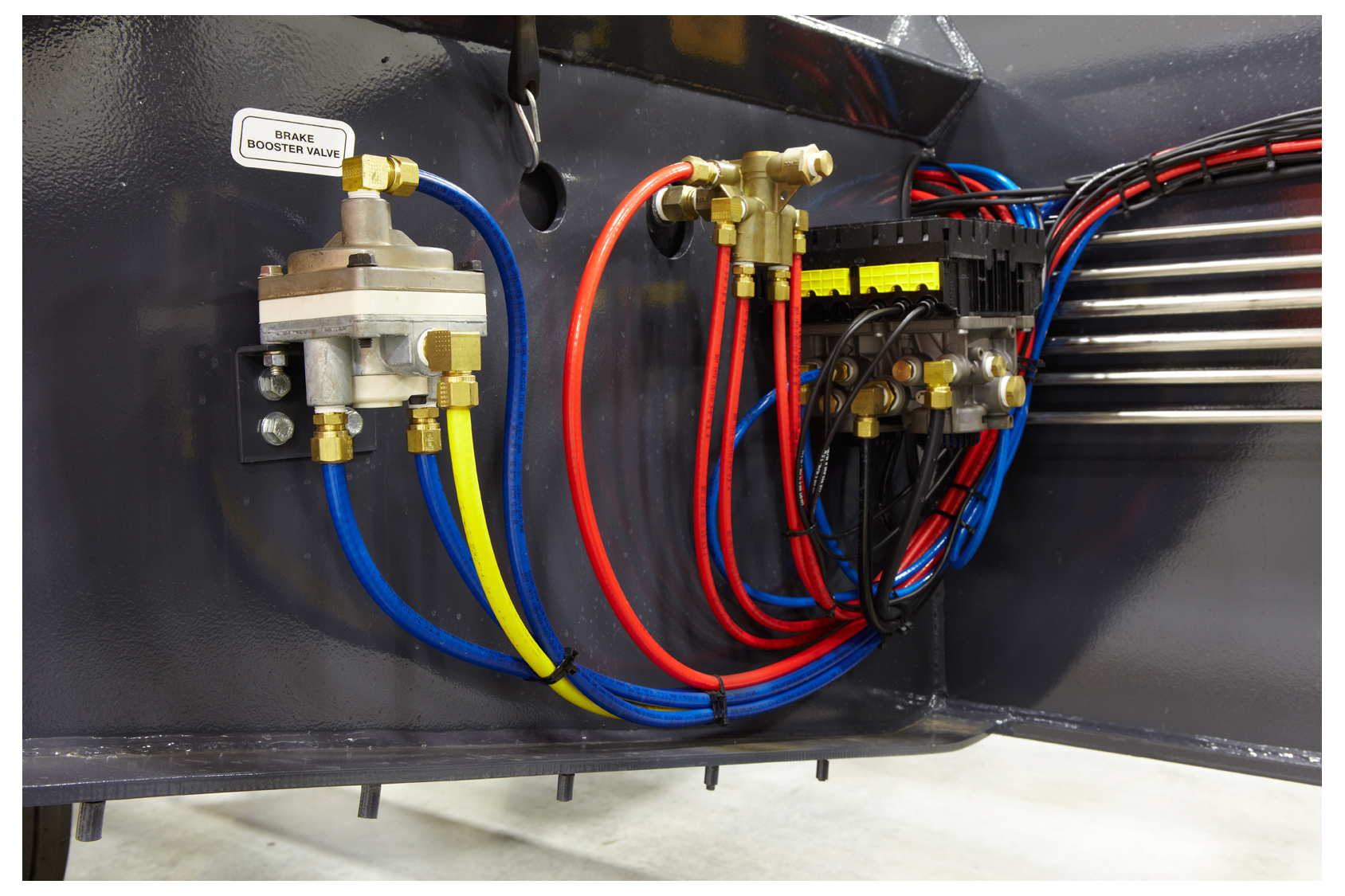

Perkins successfully moved a vessel from Cambridge, MN to Clarksville, TN atop the QUANTUM™ trailer on its maiden voyage moving a 115’ - 2” long vertical column that was 11’ - 0” in diameter and weighed 125,000 lbs. Perkins’ crew arrived at the shipper’s facility fully assembled and received the cargo quickly just as if it were a common flatbed load. Only the severe Minnesota winter conditions hampered the speed in which the load was lifted, placed and secured for transport. Because the QUANTUM™ transporter employs a three-point hydraulic suspension and electro-hydraulic steering, it proved to be highly maneuverable making turns like a 53’ dry van and completely eliminating any chance of the transfer of torsional forces to be transferred into the cargo secured to its deck.

Before the QUANTUM™ hydraulic transporter, Perkins would have used a 13-axle low profile bunk trailer with a 3+3 steerable dolly con-figuration to move this column. While Perkins still has bunk and steerable dolly configurations as options, the QUANTUM™ hydraulic transporter is a “quantum leap” from them in multiple ways. We encourage you to consider Perkins Specialized Transportation Contracting for all of your most challenging highway transportation opportunities throughout North America!

"The thing about quantum leaps is that they mark an abrupt change from one state to a distinctly different one, with no in-between transitional states being possible. It makes sense to use "quantum leap" to refer to an abrupt, radical qualitative change." ~Paul Brians

QUANTUM™ advantages over competition with bunk and steerable dolly configurations:

- Simplicity: Loading and unloading a single piece of equipment instead of a bunk trailer and dolly unit.

- Self-sufficient: QUANTUM™ arrives fully assembled at origin and requires no crane and rigging assistance on site.

- Quick to load and unload: simply place the cargo's center of gravity over the center of the trailer. With QUANTUM™ there's no positioning of dolly relative to bunk trailer. No time wasted as Perkins will not need to run air lines and electrical to rear dolly.

- Safer operations: QUANTUM™ systems are fully integrated into a single unit whereas bunk trailer and steerable dollies have to be attached to the cargo and are less safe than a unified trailer.

- Eliminates torsion: Cargo like pipe rack and process modules can be moved with ease and with the assurance they will not be exposed to torsion during transport. QUANTUM™ uses a suspension with the three pools of hydraulic support that prohibits the potential for the transfer of torsional forces from the road surfaces into the cargo during travel. In contrast, a conventional bunk and dolly system utilizes the cargo as the main structure of the trailer and all road forces are transferred throughout the piece. With the QUANTUM™, the cargo is fully supported and is along for the ride; no torsion is introduced to the piece at all.

- Vertical hydraulic stroke: This aids in avoiding low obstructions and can be be used for self-unloading to elevated storage arrangements.

- Full-length deck to support all or most of its cargo's length at multiple points without the need for steel saddles required to be welded to transporter bunks.

- Quicker cycle times on multi-piece shipments.

- Highly maneuverable: With hydraulic counter-steering capabilities on all axles to minimize turning radius, this transporter has a turning radius nominally equal to that of a 53' - 0" semi van trailer. As such Perkins has eliminated the need for a Class A CDL licensed tillerman as required by Federal motor Carrier standards Act (FMSCA) driver regulations outlined in 49 CFR 391.11 as required for operation of a steerable rear axle in bunk trailer/steer dolly combinations.